- Introduction

- Understanding does avc need digital servo Information

- The Benefits of Using Digital Servos with avc need digital servo Information

- Do All AVC Cars Require Digital Servos?

- How to Upgrade Your RC Car for avc need digital servo Information

- Troubleshooting Common Issues with AVC and Digital Servos

- Pros and Cons of Using Digital Servos with AVC

- Does AVC Need Digital Servo? Beware the Alarming Risks!

- FAQ’s

Introduction

Are you a remote-controlled car enthusiast, eager to take your racing game to the next level? If so, you’ve probably heard whispers about AVC—Active Vehicle Control. It’s a revolutionary technology that enhances stability and handling in RC cars. But here’s the million-dollar question: does AVC need a digital servo? The answer isn’t straightforward. Let’s dive into what makes digital servos tick, how they interact with AVC systems, and whether upgrading is worth it for your ride. Buckle up; we’re about to embark on an exciting journey into the world of RC vehicles!

Understanding does avc need digital servo Information

Active Vehicle Control (does avc need digital servo) is designed to provide enhanced stability and control for RC cars. It does this by adjusting power to each wheel in real-time, allowing you to maintain better traction during sharp turns or rough terrains.

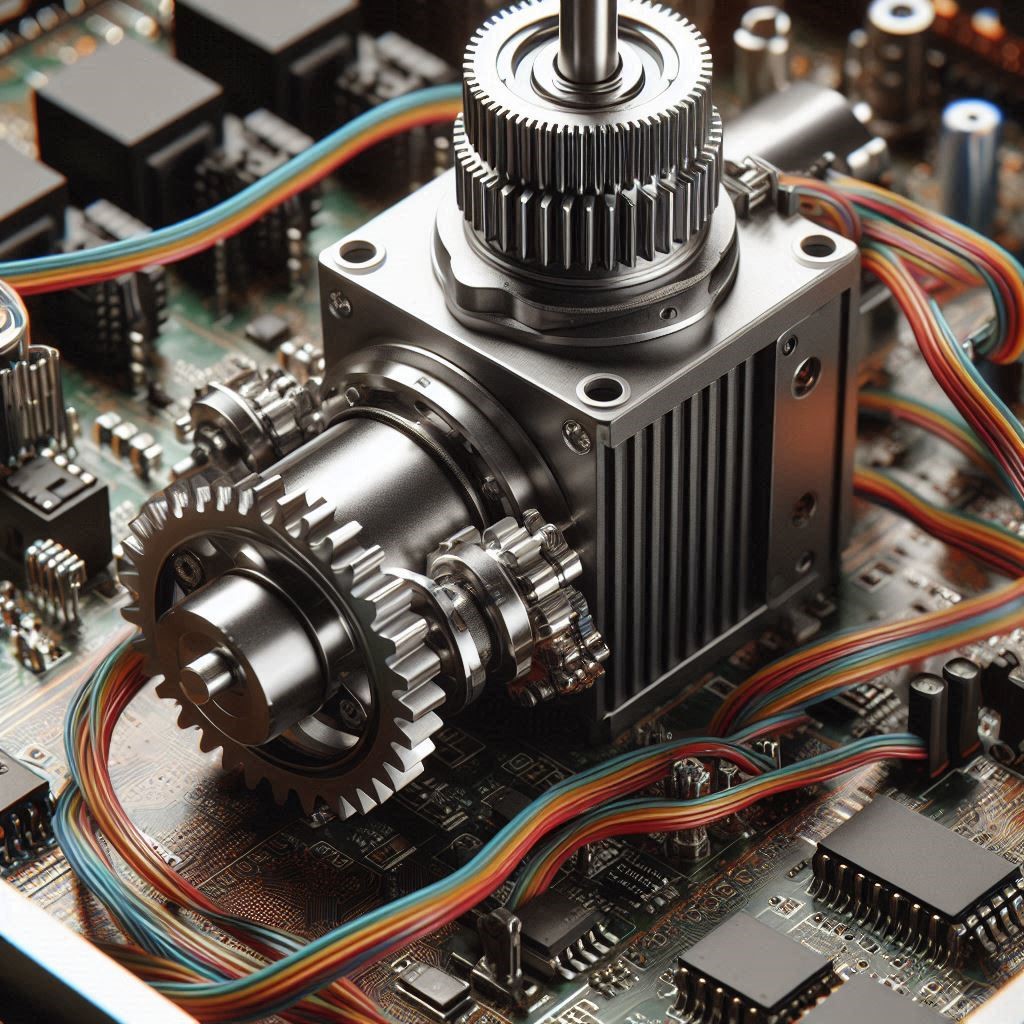

Digital servos play a crucial role in the responsiveness of does avc need digital servo systems. Unlike analog servos, digital versions offer quicker response times, which can significantly improve your vehicle’s performance. This speed is particularly beneficial when navigating challenging courses where every millisecond counts.

However, not all AVC setups require a digital servo to function effectively. Some models work perfectly well with standard analog options. Understanding the specific needs of your RC car will help you make informed decisions about whether an upgrade is necessary for achieving optimal performance.

The Benefits of Using Digital Servos with avc need digital servo Information

Digital servos offer precise control when paired with AVC systems. This precision enhances responsiveness, allowing for quicker adjustments during operation.

Another advantage is improved torque management. Digital servos can deliver consistent power, ensuring that your vehicle maintains stability even at high speeds or tricky terrains.

They also come equipped with advanced feedback mechanisms. This feature allows the servo to communicate more effectively with the AVC system, leading to smoother handling and better overall performance.

Furthermore, digital servos typically have a wider range of compatibility. Whether you’re upgrading an existing model or building a new one, they often fit seamlessly into various setups.

Their durability stands out in challenging conditions. Designed to withstand wear and tear, these servos can handle rough use without compromising functionality.

Do All AVC Cars Require Digital Servos?

Not all AVC (does avc need digital servo) cars necessitate digital servos. The requirement largely depends on the specific model and its intended use. Many entry-level models function effectively with standard analog servos.

However, as performance demands increase, particularly in competitive environments, the benefits of digital servos become apparent. Digital servos offer enhanced precision and faster response times, allowing for better handling in challenging conditions.

Some high-end AVC systems are designed to maximize compatibility with digital components. This optimization can lead to a noticeable improvement in overall vehicle responsiveness and control.

While not every AVC car requires a digital servo for operation, upgrading can enhance your driving experience significantly if you’re seeking improved performance or tackling more complex terrains. Your choice should align with your personal preferences and racing goals.

How to Upgrade Your RC Car for avc need digital servo Information

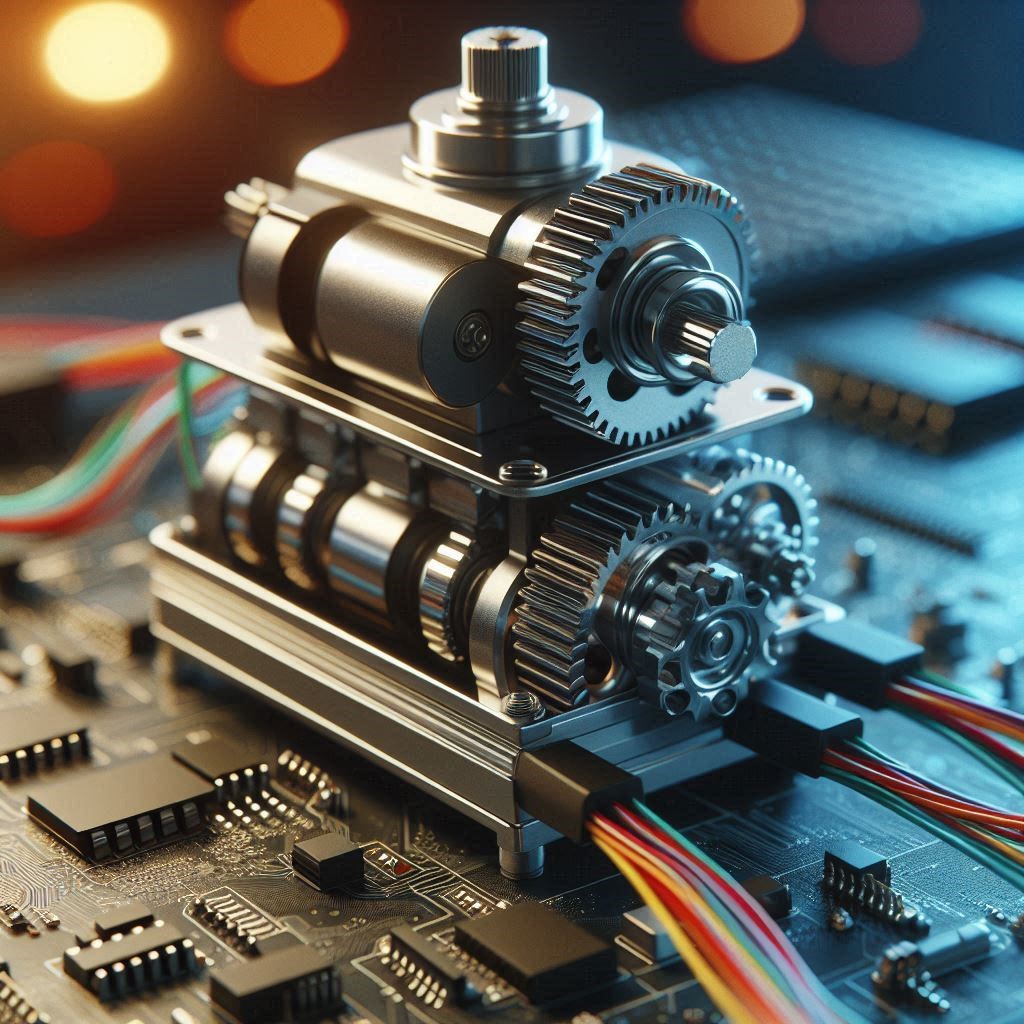

Upgrading your RC car for does avc need digital servo with a digital servo can enhance its performance significantly. Start by selecting the right digital servo that matches your vehicle’s specifications. Look for one with high torque and fast response times.

Next, you’ll need to remove the existing analog servo carefully. Disconnect any wiring and unscrew it from its mount. Ensure all components are handled gently to avoid damage.

Install the new digital servo by securing it in place and reconnecting the wires correctly. It’s essential that connections are solid to prevent any interference during operation.

After installation, recalibrate your radio system if necessary. This step will help synchronize your controls with the new setup effectively.

Don’t forget to take your upgraded RC car for a test run! Adjust settings as needed based on how it performs on various terrains.

Troubleshooting Common Issues with AVC and Digital Servos

When working with AVC (does avc need digital servo) systems and digital servos, several issues can arise. One common problem is a lack of responsiveness. This could stem from poor connections or insufficient power supply to the servo.

Another frequent issue involves erratic movements. If your car doesn’t steer properly, check for any binding in the linkages or ensure that the servo isn’t damaged.

Sometimes, users report jittery control at certain speeds. This may be linked to incorrect settings on your AVC system. Tuning those parameters can make a significant difference.

Overheating is another concern with digital servos when paired with AVC systems. Ensure adequate cooling measures are in place and avoid prolonged use without breaks to preserve functionality and performance.

| Feature | With Digital Servo | Without Digital Servo |

|---|---|---|

| Accuracy | High | Moderate |

| Response Time | Fast | Slower |

| Control Precision | High | Moderate |

| Feedback Mechanism | Advanced (Digital) | Basic (Analog) |

| Customization Options | Extensive | Limited |

| Ease of Integration | Easier with digital controls | May require additional adaptation |

| System Complexity | Higher | Lower |

| Cost | Higher | Lower |

| Maintenance Requirements | Lower (due to precision) | Higher (due to potential drift) |

| Power Consumption | Lower | Higher |

| Durability | High | Moderate |

| Programming Flexibility | High | Limited |

| Software Compatibility | Wide | Limited |

| Noise Levels | Low | Higher |

| Real-Time Adjustments | Smooth and precise | Less smooth |

| Use Case Scenarios | High-precision applications, automation | Basic control tasks, less demanding environments |

Descriptions of Features:

- Accuracy: The degree to which the system can precisely control and measure the desired parameters.

- Response Time: The speed at which the system responds to control inputs or changes.

- Control Precision: The level of detail and exactness in the control of the system.

- Feedback Mechanism: The method used for receiving and processing feedback in the system (digital for higher accuracy, analog for simpler setups).

- Customization Options: The extent to which the system can be tailored to specific needs or applications.

- Ease of Integration: How straightforward it is to integrate the system with other components or systems.

- System Complexity: The overall complexity of the system, including hardware and software requirements.

- Cost: The financial cost associated with the system, including initial investment and ongoing expenses.

- Maintenance Requirements: The level of maintenance needed to keep the system operating effectively.

- Power Consumption: The amount of power the system consumes during operation.

- Durability: The ability of the system to withstand wear, pressure, or damage.

- Programming Flexibility: The ease with which the system can be programmed or reprogrammed for different tasks.

- Software Compatibility: The range of software applications that can be used with the system.

- Noise Levels: The amount of noise generated by the system during operation.

- Real-Time Adjustments: The ability to make precise adjustments in real-time.

- Use Case Scenarios: Typical applications or environments where the system is most effectively utilized.

Pros and Cons of Using Digital Servos with AVC

Digital servos can enhance the performance of your does avc need digital servo system. They offer precise control and faster response times, making them ideal for dynamic driving conditions. When you’re navigating tricky terrains or racing against time, this accuracy gives you an edge.

However, there are downsides to consider. Digital servos often come with a higher price tag compared to their analog counterparts. This might not suit every budget.

Additionally, digital servos require more power. If your setup isn’t optimized for this demand, it could lead to battery drain during crucial moments on the track.

Installation may be complex for beginners. Understanding how to integrate these components with AVC requires some technical know-how and patience.

Balancing these advantages and disadvantages is essential in deciding whether digital servos are right for your AVC setup.

Does AVC Need Digital Servo? Beware the Alarming Risks!

When considering whether does avc need digital servo, it’s crucial to weigh both the advantages and potential pitfalls. Digital servos offer improved precision, faster response times, and enhanced control—benefits that can elevate your RC car’s performance significantly. However, there are risks involved with this upgrade.

One major concern is compatibility. Not all AVC systems work seamlessly with digital servos; mismatched components can lead to erratic behavior or even damage your setup. Moreover, while many digital servos boast higher torque ratings, they may also drain battery life more quickly than their analog counterparts. This could leave you stranded mid-race if you’re not careful.

Another factor to consider is cost. Digital servos tend to be pricier than traditional ones, which might be an issue for hobbyists on a budget who are looking for maximum value without sacrificing performance.

It’s essential to conduct thorough research before making any decisions regarding upgrading your AVC system with a digital servo. Evaluate what you truly need from your RC experience and ensure you’re prepared for any challenges that may arise along the way.

While the integration of a digital servo into an AVC system presents exciting opportunities for enhanced control and responsiveness in racing scenarios, it’s imperative to stay informed about possible complications related to compatibility and performance trade-offs. Proceeding without due diligence could lead you down an unanticipated path of frustration rather than enjoyment in your hobby!

FAQ’s

What is AVC (Automatic Voltage Control)?

What is a digital servo in the context of AVC systems?

Does an AVC system need a digital servo to function properly?

What are the benefits of using a digital servo in an AVC system?

Enhanced Precision: Digital servos provide high accuracy in controlling voltage regulation.

Faster Response: They can quickly adjust to changes in voltage or load conditions.

Improved Stability: Digital technology allows for finer control, reducing voltage fluctuations and improving system stability.

Advanced Features: Digital servos often come with programmable features and diagnostics that can enhance the overall performance of the AVC system.

Can an AVC system function without a digital servo, and what are the alternatives?

How do I determine if my AVC system requires a digital servo?

Precision Requirements: If high accuracy and fast response are critical, a digital servo might be necessary.

System Specifications: Review the technical requirements and specifications of your AVC system to see if a digital servo is recommended or required.

Performance Goals: Assess your performance goals and whether a digital servo aligns with those goals.

Consult Experts: Consult with the manufacturer or a system integrator to get professional advice tailored to your specific AVC system and application.